CRACK TREATMENT OF THE ASPHALT BINDER COURSE

Main Break Water(MBW) access road occurs several cracks on the asphalt binder course. The road cracks are monitored and investigated with specialist from RDA Research & Development. This report describes the reason and remedial method of the cracks based on the investigation and consultation.

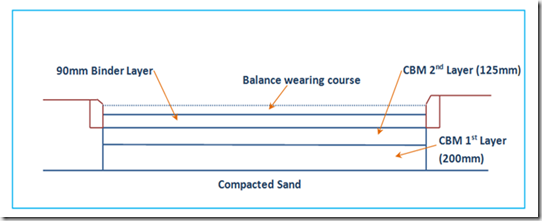

MBW access road structure consists of fallowing cross section and the core samples have been taken on the cracks.

According to core sample data, can be observed that the crack was started from CBM and reflected to the binder course surface.

CRACK INVESTIGATION

The crack survey carried out for the entire road and investigation detail summarized as an attached sheet. Core samples were taken from the jointly selected locations with the engineer. MBW access road cracks were categorized into two types based on crack surface appearance.

- Transverse cracks

- Longitudinal cracks

Transverse cracks

Transverse cracks were occurred as a perpendicular to the road center line. These cracks are reflecting from the CBM layers.

- According to core sample data, can be identified the fallowing crack types was happened.

- Some of cracks were occurred from CBM 2st layer and reflected to the binder course surface.

- Other cracks are started from CBM bottom layer (1st layer) and reflected to the binder course.

Longitudinal cracks

Longitudinal cracks were occurred as a parallel to the road centerline and which was happened due to the reflection of the CBM longitudinal joint.

PROPOSAL FOR REPAIR OF CRACK

Proposal of the crack repairing method is introduced by specialist from RDA Research & Development.

Three conditions for reflection cracks on CBM :

- Cracks in the base layer must be wide enough to generate stress conditions in the asphalt surface.

- There is no method available to relieve the stress concentrations.

- The asphalt is brittle enough to crack due to upwards propagation of the stress concentration.

In most cases, reflection cracks are narrow (less than 3mm) and will not adversely affect the performance of the pavement. But all the cracks on MBW access road will be treated to prevent from the possibility of propagation.

As per the specialist’s proposal, Geo-Fabric material will be applied along the cracks of the binder course before laying the wearing course in accordance with manufacturer’s instructions.

CRACK REPAIRING

Proposed Material

- Polyfelt (PGM-G 50/50) to be used, material details is in Appendix

Manpower

- Supervisor

- Skilled Labours

- Unskilled Labours

Sequence

Methodology

Identify the crack locations and properly cleaning by air compressor.

Bring the notification to the site representative of the Engineer.

The binder surface is thoroughly cleaned and free from all the traces of dust and any of unsound materials.

Cut the Ploy paving Fabric (PGM 50/50) for required length of the crack and 0.5m offset from the crack as following the sketch.

3 Comments:

Thank you for this helpful info! We really learned a lot from your detailed crack repair process. At our concrete driveway Clearwater business, we know how important it is to treat damage early. Big thanks to the blog owner for sharing this—it's great to see your dedication to strong, lasting roads!

Thank you for this detailed info! It's helpful to see how cracks form and how to fix them right. We handle concrete driveway Augusta projects, so learning about binder course issues and crack treatment gives us new ideas for our work too. Great job and thanks for sharing your process!

Thanks for sharing this helpful info! We learned a lot from your detailed steps on fixing cracks. As Augusta fencing contractors, we also value strong foundations. Your post gave us ideas to better care for surfaces near our fence installs. We appreciate your expertise and time!

Post a Comment

Subscribe to Post Comments [Atom]

<< Home